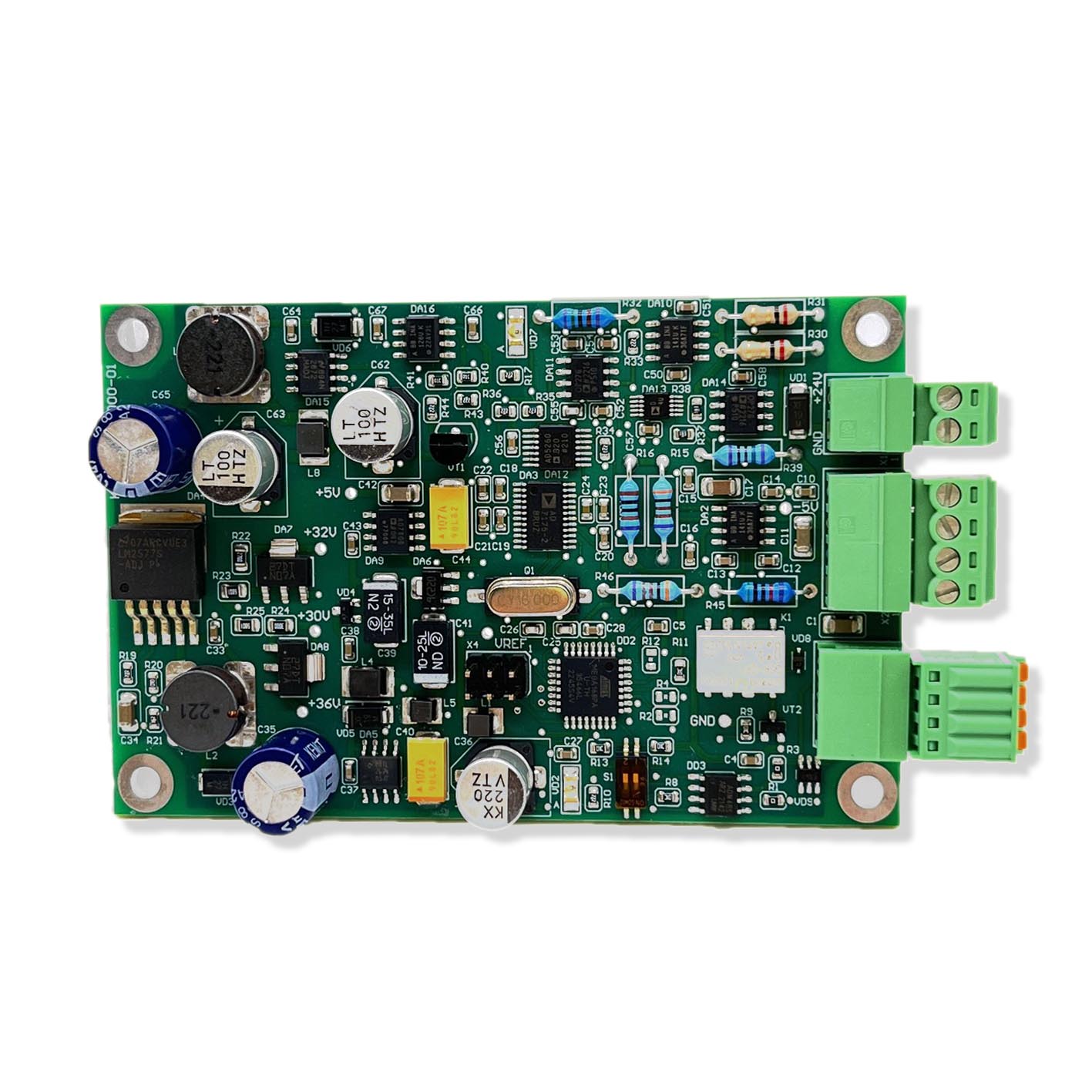

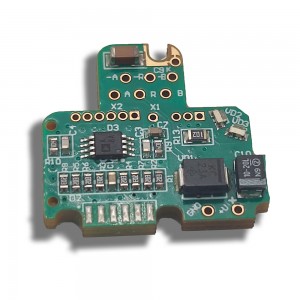

4 Zigawo 2.0mm makulidwe ndi 1oz Copper Green Mask Printed Circuit Assembly Board

Zambiri zopanga

| Chitsanzo No. | PCB-A41 |

| Phukusi lamayendedwe | Vacuum Packing |

| Chitsimikizo | UL, ISO9001&ISO14001,RoHS |

| Matanthauzo | Gawo la IPC2 |

| Malo Ocheperako/Mzere | 0.075mm / 3mil |

| Chiyambi | Chopangidwa ku China |

| Mphamvu Zopanga | 720,000 M2/Chaka |

| Kugwiritsa ntchito | Consumer Electronics |

Mafotokozedwe Akatundu

PCBA Projects Chiyambi

Kampani ya ABIS CIRCUITS imapereka ntchito, osati zogulitsa zokha.Timapereka mayankho, osati katundu wokha.

Kuchokera pakupanga kwa PCB, zinthu zomwe zimagulidwa kuzinthuzo zimasonkhana.Mulinso:

PCB Custom

Zojambula / kapangidwe ka PCB molingana ndi chithunzi chanu

Kupanga kwa PCB

Kupeza chigawo

Kusonkhana kwa PCB

PCBA 100% mayeso

Ubwino Wathu

Makina apamwamba kwambiri othamanga kwambiri a Pick and Place Machines omwe amatha kukonza zinthu pafupifupi 25,000 za SMD pa ola limodzi.

Kuthekera kokwanira kokwanira 60K Sqm pamwezi-Kupereka voliyumu yotsika komanso kupanga PCB yomwe ikufunika, komanso kupanga kwakukulu

Akatswiri opanga ma engineering 40 ndi nyumba zawo zopangira zida, zolimba ku OEM.Imapereka njira ziwiri zosavuta: Chidziwitso chamwambo ndi Chokhazikika Chozama cha IPC Class II ndi III Miyezo

Timapereka chithandizo chokwanira cha EMS kwa makasitomala omwe akufuna kuti tisonkhanitse PCB ku PCBA, kuphatikiza ma prototypes, projekiti ya NPI, voliyumu yaying'ono ndi yapakatikati.Timathanso kupeza zigawo zonse za polojekiti yanu ya PCB.Akatswiri athu ndi gulu lothandizira ali ndi chidziwitso chochuluka pamakampani ogulitsa ndi EMS, ndi chidziwitso chakuya mumsonkhano wa SMT kulola kuthetsa mavuto onse opanga.Ntchito yathu ndiyotsika mtengo, yosinthika, komanso yodalirika.Takhutiritsa makasitomala m'mafakitale ambiri kuphatikiza zamankhwala, mafakitale, zamagalimoto ndi zamagetsi ogula.

PCBA luso

| 1 | Msonkhano wa SMT kuphatikiza msonkhano wa BGA |

| 2 | Tchipisi zovomerezeka za SMD: 0204, BGA, QFP, QFN, TSOP |

| 3 | Chigawo kutalika: 0.2-25mm |

| 4 | Kupaka kwa mphindi: 0204 |

| 5 | Min mtunda pakati pa BGA : 0.25-2.0mm |

| 6 | Min BGA kukula: 0.1-0.63mm |

| 7 | Min QFP danga: 0.35mm |

| 8 | Min msonkhano kukula: (X * Y): 50 * 30mm |

| 9 | Max msonkhano kukula: (X * Y): 350 * 550mm |

| 10 | Kusankha-kuyika mwatsatanetsatane: ± 0.01mm |

| 11 | Kuthekera koyika: 0805, 0603, 0402 |

| 12 | High pin count press fit ikupezeka |

| 13 | Kuchuluka kwa SMT patsiku: 80,000 points |

Kuthekera - SMT

| Mizere | 9 (5 Yamaha, 4KME) |

| Mphamvu | 52 miliyoni amayika pamwezi |

| Max Board Kukula | 457 * 356mm (18"X14") |

| Min Chigawo kukula | 0201-54 sq.mm.(0.084 sq.inch), cholumikizira chachitali,CSP,BGA,QFP |

| Liwiro | 0.15 sec/chip, 0.7 sec/QFP |

Kuthekera - PTH

| Mizere | 2 |

| Max board wide | 400 mm |

| Mtundu | Mafunde apawiri |

| Pbs status | Thandizo la mzere wopanda kutsogolo |

| Kutentha kwakukulu | 399 digiri C |

| Utsi flux | phatikiza |

| Pre-kutentha | 3 |

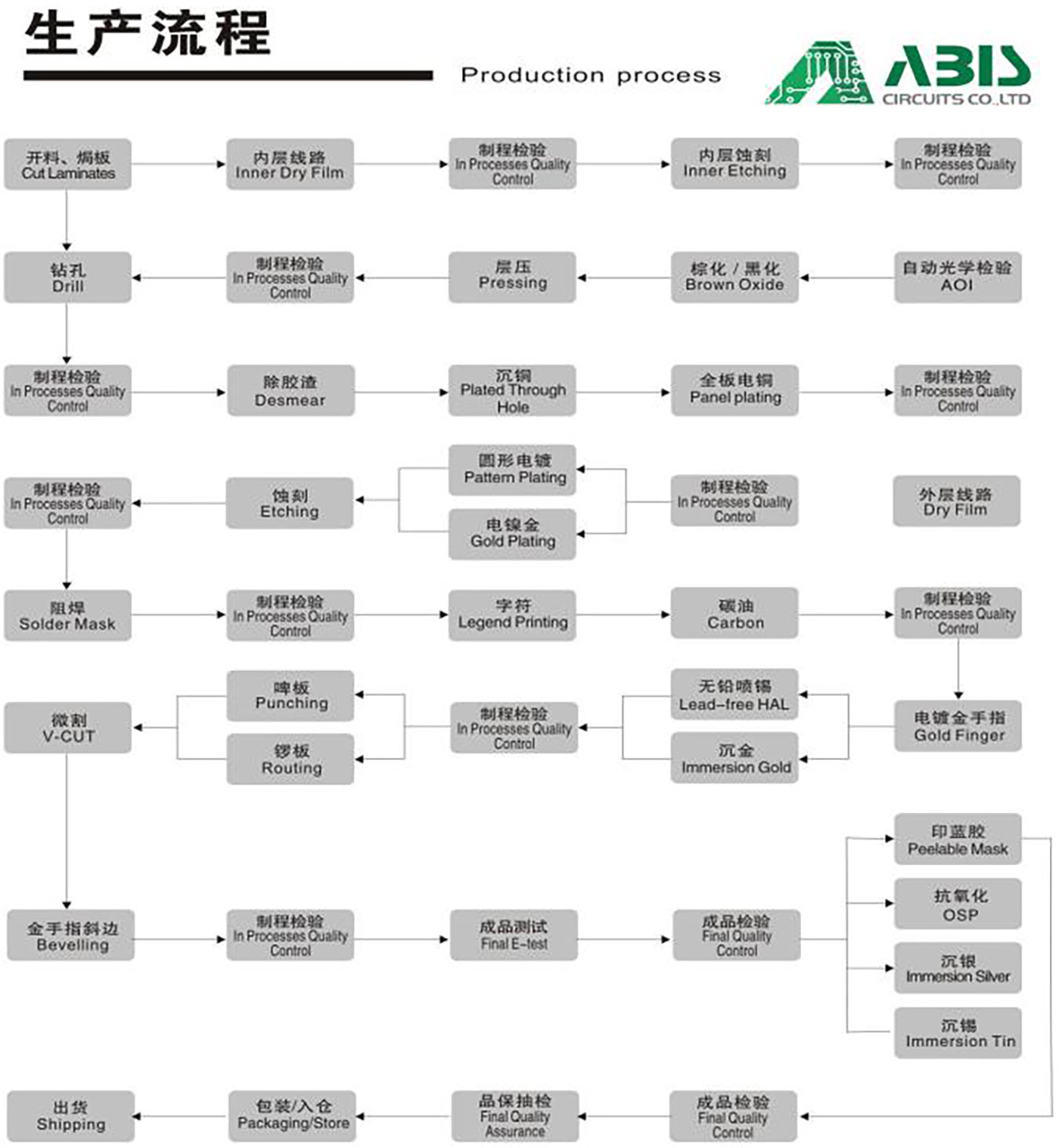

Njira Zopangira

Kulandira Zinthu → IQC → Stock → Material to SMT → SMT Line Loading → Solder Paste/Glue Printing → Chip Mount → Reflow → 100% Kuyang'ana Zowoneka → Kuyendera Kokha (AOI) → SMT QC Sampling → SMT PTH → Material PTH Kukwezera Mzere → Wokulungidwa Kupyolera Mbowo → Kuwotchera Mafunde → Gwirani Mmwamba → 100% Kuyang'ana Zowoneka → PTH QC Zitsanzo → Mayeso Ozungulira (ICT) → Final Assembly → Functional Test (FCT) → Packing → OQC Sampling → Kutumiza

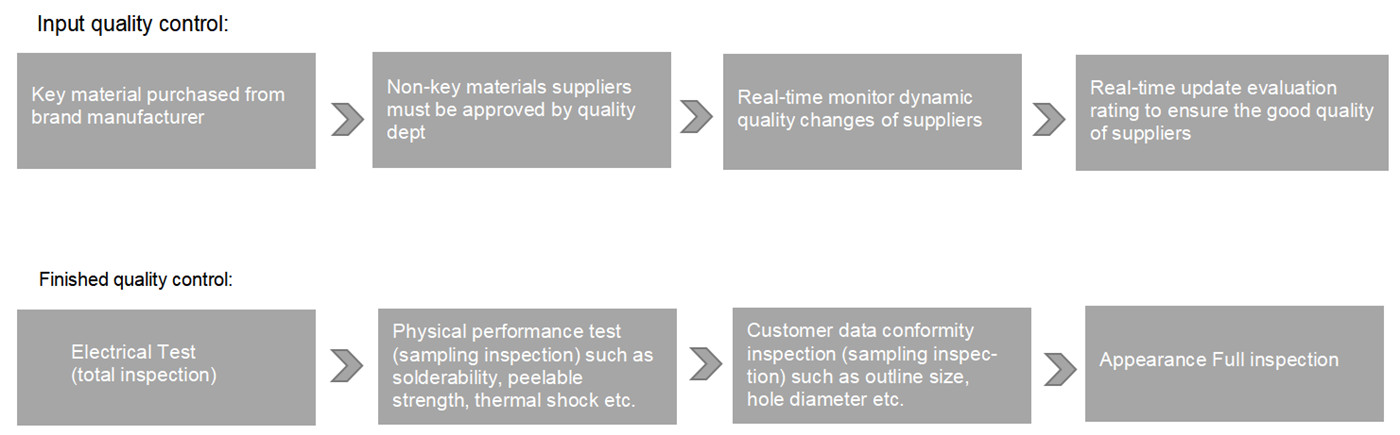

Kuwongolera Kwabwino

| Kuyesa kwa AOI | Macheke a solder phala Kufufuza kwa zigawo mpaka 0201 Imayang'ana zigawo zomwe zikusowa, kuchotsera, magawo olakwika, polarity |

| Kuwunika kwa X-ray | X-ray imapereka kuwunika kwakukulu kwa: BGAs/Micro BGAs/Chip sikelo phukusi / Bare board |

| Kuyesa M'dera | Kuyezetsa kwapakati kumagwiritsidwa ntchito molumikizana ndi AOI kuchepetsa kuwonongeka kwa magwiridwe antchito chifukwa cha zovuta zamagulu. |

| Mayeso amphamvu | Mayeso apamwamba a Ntchito Flash Chipangizo Programming Kuyesa kogwira ntchito |

Satifiketi

FAQ

| Gulu | Nthawi Yachangu Kwambiri | Nthawi Yomwe Amatsogolera |

| Mbali ziwiri | 24hrs | 120hrs |

| 4 zigawo | 48hrs | 172 maola |

| 6 Zigawo | 72hrs | 192 maola |

| 8 zigawo | 96hrs | 212hrs |

| 10 zigawo | 120hrs | 268hrs |

| 12 Zigawo | 120hrs | 280hrs |

| 14 Zigawo | 144 maola | 292hrs |

| 16-20 Zigawo | Zimatengera zofunikira zenizeni | |

| Pamwamba pa 20 Layers | Zimatengera zofunikira zenizeni | |

Bill of materials (BOM) yofotokoza:

a), Zigawo za opanga manambala,

b), Nambala ya zigawo za othandizira (mwachitsanzo Digi-key, Mouser, RS)

c), zithunzi za PCBA ngati nkotheka.

d), kuchuluka

| Mphamvu yopangira zinthu zogulitsa zotentha | |

| Double Side/Multilayer PCB Workshop | Aluminium PCB Workshop |

| luso luso | luso luso |

| Zida: CEM-1, CEM-3, FR-4(High TG), Rogers, TELFON | Zida zopangira: Aluminium base, Copper base |

| Layer: 1 wosanjikiza mpaka 20 zigawo | Layer: 1 wosanjikiza ndi 2 zigawo |

| Min.line m'lifupi/danga: 3mil/3mil(0.075mm/0.075mm) | Min.line m'lifupi/danga: 4mil/4mil(0.1mm/0.1mm) |

| Min.Hole kukula: 0.1mm(bowo lodulira) | Min.Bowo kukula: 12mil (0.3mm) |

| Max.Kukula kwa board: 1200mm * 600mm | Max.Board kukula: 1200mm* 560mm(47in* 22in) |

| Kumapeto kwa bolodi: 0.2mm-6.0mm | Anamaliza bolodi makulidwe: 0.3 ~ 5mm |

| Makulidwe a zojambula zamkuwa: 18um ~ 280um (0.5oz ~ 8oz) | Makulidwe a zojambula zamkuwa: 35um ~ 210um (1oz ~ 6oz) |

| NPTH Hole Kulekerera: +/- 0.075mm, PTH dzenje Kulekerera: +/-0.05mm | Kulekerera kwa dzenje: +/-0.05mm |

| Kulekerera kwadongosolo: +/-0.13mm | kulolerana kwamayendedwe: +/ 0.15mm;kulolerana nkhonya autilaini: +/ 0.1mm |

| Pamwamba pomaliza: HASL yopanda kutsogolera, golide womiza (ENIG), siliva womiza, OSP, plating yagolide, chala chagolide, Carbon INK. | Pamwamba Pamwamba: Kutsogolera kwaulere HASL, golide womiza (ENIG), siliva womiza, OSP etc |

| Kulekerera kwa Impedans: +/- 10% | Kulekerera kwa makulidwe: +/-0.1mm |

| Kuthekera kopanga: 50,000 sqm/mwezi | MC PCB Kupanga mphamvu: 10,000 sqm/mwezi |

Ayi, sitingathekuvomerezamafayilo azithunzi, ngati mulibeGerberfile, mungatitumizire zitsanzo kuti tikopere.

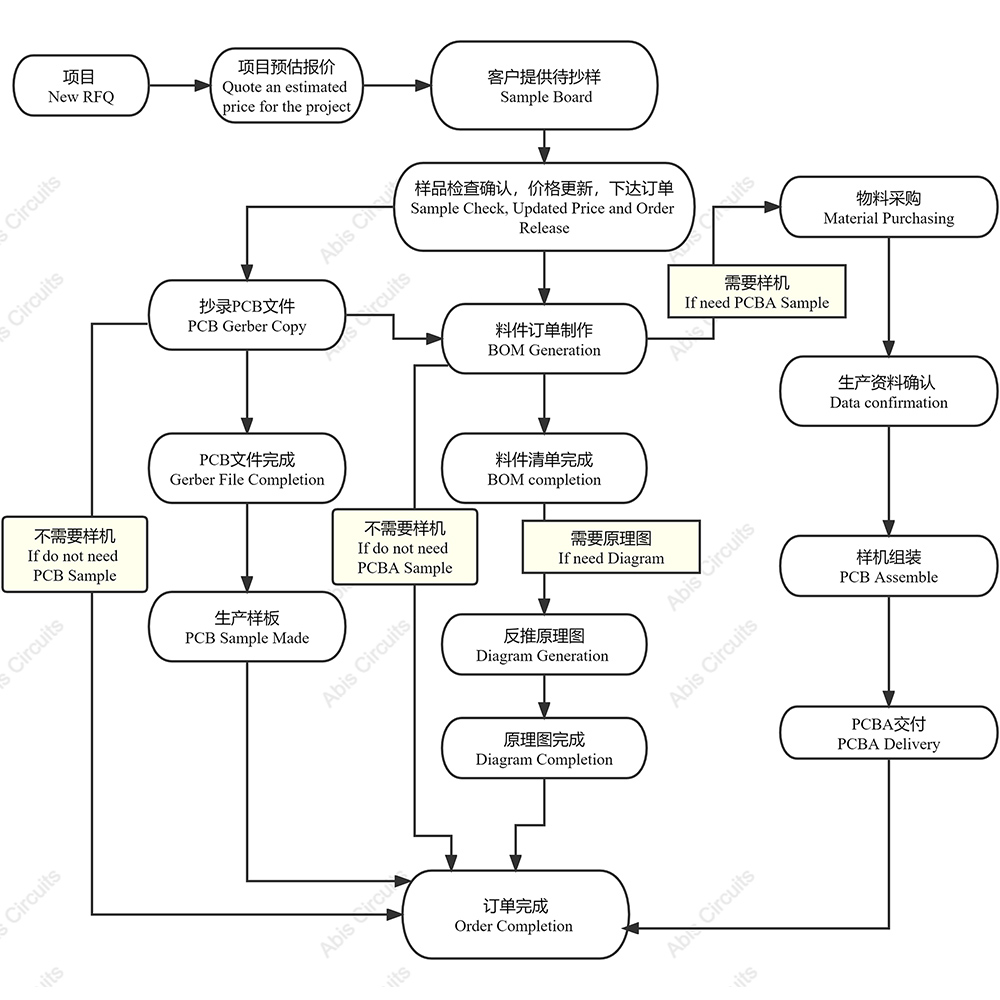

PCB&PCBA Copy process:

Njira Zathu Zotsimikizira Ubwino monga zili pansipa:

a), Kuyang'anira Zowoneka

b), kafukufuku wowuluka, chida chokonzekera

c), Kuwongolera kwa Impedans

d), Kuzindikira luso la Solder

e), Digital metallogric microscope

f), AOI (Automated Optical Inspection)

ABlS imayang'ana 100% zowoneka ndi AOl komanso kuyesa magetsi, kuyesa kwamagetsi apamwamba, kuyesa kuwongolera kwamphamvu, magawo ang'onoang'ono, kuyesa kugwedezeka kwamafuta, kuyesa kwa solder, kuyesa kudalirika, kuyezetsa kukana kwa insulating, kuyezetsa ukhondo wa ionic ndi kuyesa kwa PCBA Functional.

Makampani Akuluakulu a ABIS: Industrial Control, Telecommunication, Automotive Products and Medical.Msika Waukulu wa ABIS: 90% Msika Wapadziko Lonse (40% -50% waku USA, 35% ku Europe, 5% ku Russia ndi 5% -10% ku East Asia) ndi 10% Msika Wapakhomo.

Kutumiza pa nthawi kumaposa 95%

a), kutembenukira mwachangu kwa maola 24 kwa PCB yam'mbali iwiri

b), 48hours 4-8 zigawo chitsanzo PCB

c), 1 ola la mawu

d), maola 2 a funso la injiniya/madandaulo

e), maola 7-24 othandizira luso / kuyitanitsa ntchito / ntchito zopanga

·Ndi ABIS, makasitomala amachepetsa kwambiri komanso moyenera mtengo wawo wogula padziko lonse lapansi.Kuseri kwa ntchito iliyonse yoperekedwa ndi ABIS, imabisika kupulumutsa mtengo kwa makasitomala.

.Tili ndi mashopu awiri limodzi, imodzi ndi yachitsanzo, yotembenuka mwachangu, ndi kupanga ma voliyumu ang'onoang'ono.Zina ndi zopanga zambiri komanso za board ya HDI, yokhala ndi antchito aluso kwambiri, yopangira zinthu zapamwamba zokhala ndi mitengo yopikisana komanso kutumiza munthawi yake.

.Timapereka zogulitsa zaukadaulo kwambiri, chithandizo chaukadaulo komanso mayendedwe, padziko lonse lapansi ndi maola 24 odandaula.