6 Layers FR4 HDI PCB Circuit mu 2oz copper yokhala ndi Immersion Tin Surface Yatha

Basic Info

| Chitsanzo No. | PCB-A12 |

| Phukusi lamayendedwe | Vacuum Packing |

| Chitsimikizo | UL, ISO9001&ISO14001,RoHS |

| Kugwiritsa ntchito | Consumer electronics |

| Malo Ocheperako/Mzere | 0.075mm / 3mil |

| Mphamvu Zopanga | 50,000 sqm / mwezi |

| HS kodi | 853400900 |

| Chiyambi | Chopangidwa ku China |

Mafotokozedwe Akatundu

Chiyambi cha HDI PCB

HDI PCB imatanthauzidwa ngati bolodi losindikizidwa lokhala ndi kachulukidwe kakang'ono ka waya pagawo lililonse kuposa PCB wamba.Iwo ali ndi mizere yowongoka kwambiri ndi malo, ma vias ang'onoang'ono ndi mapepala ojambulira, komanso kachulukidwe kapamwamba kolumikizira kuposa momwe amagwiritsidwira ntchito muukadaulo wamba wa PCB.HDI PCBs amapangidwa kudzera ma microvias, kukwiriridwa vias ndi sequential lamination ndi kutchinjiriza zipangizo ndi kondakitala mawaya kwa kachulukidwe apamwamba a mayendedwe.

Mapulogalamu

HDI PCB ntchito kuchepetsa kukula ndi kulemera, komanso kumapangitsanso magetsi ntchito chipangizo.HDI PCB ndiye njira yabwino kwambiri yosinthira kuwerengera kwapamwamba komanso mtengo wamtengo wapatali wa laminate kapena matabwa otsatizana.HDI imaphatikiza ma vias akhungu ndi okwiriridwa omwe amathandizira kupulumutsa malo enieni a PCB polola mawonekedwe ndi mizere kuti ipangidwe pamwamba kapena pansi pawo popanda kupanga kulumikizana.Zambiri zamasiku ano zabwino za BGA ndi zopindika za chip-chip sizimalola kutsata pakati pa BGA pads.Akhungu ndi m'manda vias kokha kulumikiza zigawo amafuna kugwirizana m'dera limenelo.

Ukatswiri & Kutha

| Kanthu | Mphamvu Zopanga |

| Mawerengedwe a Layer | 1-20 zigawo |

| Zakuthupi | FR-4, CEM-1/CEM-3, PI, High Tg, Rogers, PTEF, Alu/Cu Base, etc. |

| Board makulidwe | 0.10mm-8.00mm |

| Kukula Kwambiri | 600mmX1200mm |

| Kulekerera kwa Board Outline | + 0.10 mm |

| Makulidwe kulolerana (t≥0.8mm) | ± 8% |

| Makulidwe kulolerana (t<0.8mm) | ±10% |

| Insulation Layer Makulidwe | 0.075mm-5.00mm |

| Minimum Line | 0.075 mm |

| Malo Ocheperako | 0.075 mm |

| Out Layer Copper Makulidwe | 18um--350um |

| Makulidwe a Mkuwa Wamkati | 17um--175um |

| Drilling Hole(Mechanical) | 0.15mm-6.35mm |

| Malizitsani Bowo (Mechanical) | 0.10mm-6.30mm |

| Kulekerera Diameter (Mechanical) | 0.05 mm |

| Kulembetsa (Mechanical) | 0.075 mm |

| Mbali Ration | 16:1 |

| Mtundu wa Mask wa Solder | LPI |

| SMT Mini.Solder Mask Width | 0.075 mm |

| Mini.Kuchotsa Mask a Solder | 0.05 mm |

| Pulagi Hole Diameter | 0.25mm--0.60mm |

| Kulekerera kwa Impedans | ±10% |

| Pamwamba kumaliza/mankhwala | HASL, ENIG, Chem, Tin, Flash Golide, OSP, Chala Chagolide |

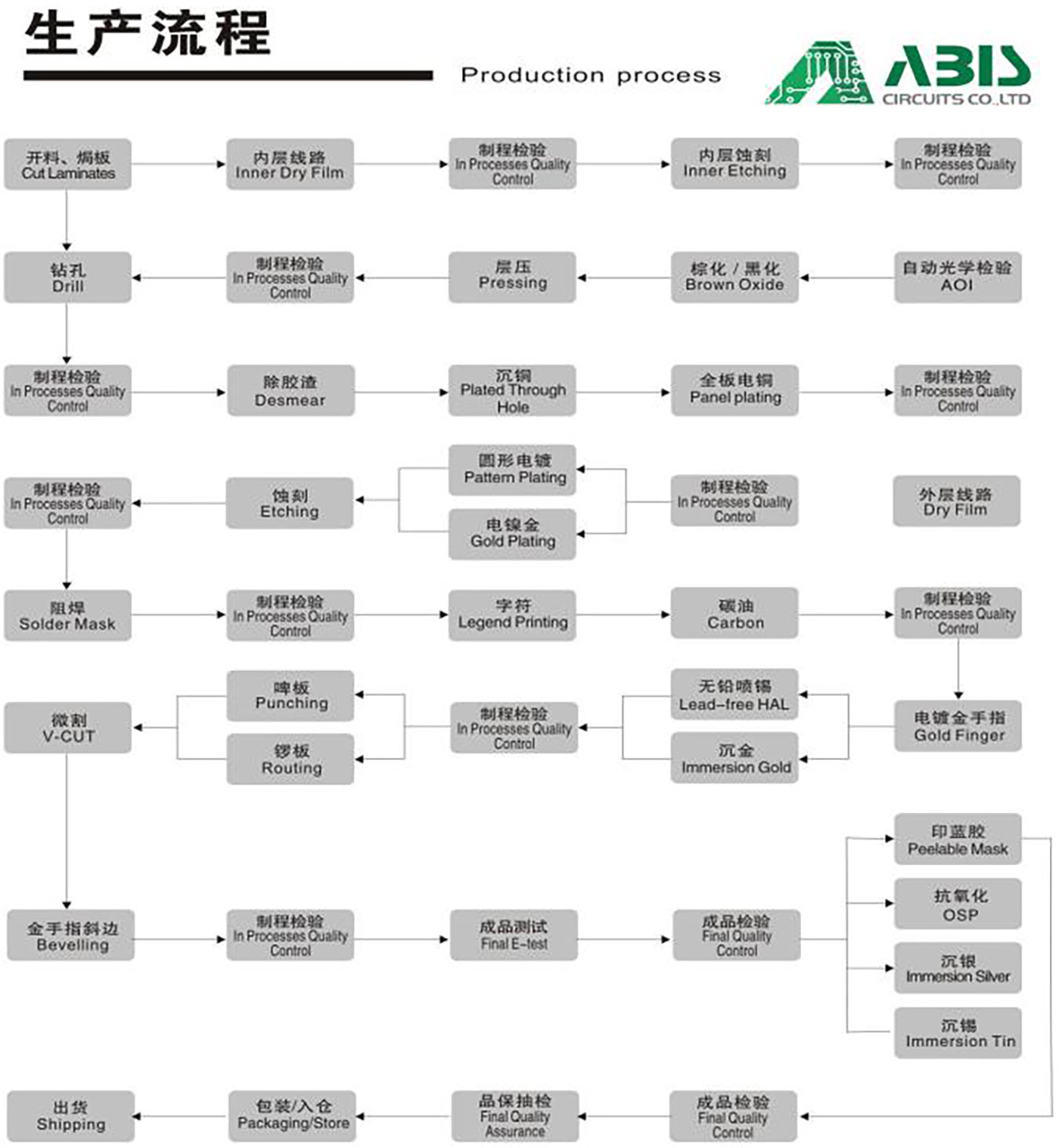

PCB Production process

Njirayi imayamba ndikupanga Mapangidwe a PCB pogwiritsa ntchito pulogalamu iliyonse ya PCB / CAD Tool (Proteus, Eagle, Or CAD).

Masitepe ena onse ndi a Manufacturing Process of Rigid Printed Circuit Board ndi ofanana ndi Single Sided PCB kapena Double Sided PCB kapena Multi-layer PCB.

Q/T Nthawi Yotsogolera

| Gulu | Nthawi Yachangu Kwambiri | Nthawi Yomwe Amatsogolera |

| Mbali ziwiri | 24hrs | 120hrs |

| 4 zigawo | 48hrs | 172 maola |

| 6 Zigawo | 72hrs | 192 maola |

| 8 zigawo | 96hrs | 212hrs |

| 10 zigawo | 120hrs | 268hrs |

| 12 Zigawo | 120hrs | 280hrs |

| 14 Zigawo | 144 maola | 292hrs |

| 16-20 Zigawo | Zimatengera zofunikira zenizeni | |

| Pamwamba pa 20 Layers | Zimatengera zofunikira zenizeni | |

Kusuntha kwa ABIS kuwongolera FR4 PCBS

Kukonzekera kwa dzenje

Kuchotsa zinyalala mosamala & kusintha magawo makina kubowola: pamaso plating kudutsa ndi mkuwa, ABIS amapereka chidwi kwambiri mabowo onse pa FR4 PCB wochitiridwa kuchotsa zinyalala, zosokoneza pamwamba, ndi epoxy smear, mabowo oyera amaonetsetsa plating bwinobwino kumamatira pabowo makoma. .komanso, kumayambiriro kwa ndondomekoyi, magawo a makina obowola amasinthidwa molondola.

Kukonzekera Pamwamba

Kuwononga mosamala: Ogwira ntchito zaukadaulo odziwa bwino ntchito adzazindikira pasadakhale kuti njira yokhayo yopewera zotsatira zoyipa ndikudikirira kufunikira kosamalira mwapadera ndikutenga njira zoyenera kuonetsetsa kuti ntchitoyi ikuchitika mosamala komanso moyenera.

Kuwonjeza kwa Matenthedwe

Wozolowera kuthana ndi zinthu zosiyanasiyana, ABIS azitha kusanthula kuphatikiza kuti atsimikizire kuti ndi koyenera.ndiye kusunga kudalirika kwa nthawi yayitali kwa CTE (coefficient of thermal expansion), ndi CTE yapansi, zocheperapo zomwe zimakutidwa ndi mabowo zimatha kulephera kusinthasintha mobwerezabwereza mkuwa womwe umapanga zolumikizira zamkati.

Kukulitsa

Kuwongolera kwa ABIS kuzungulirako kumakulitsidwa ndi magawo odziwika poyembekeza kutayika kumeneku kuti zigawozo zibwerere ku miyeso yomwe idapangidwa pambuyo pomaliza.komanso, pogwiritsa ntchito malangizo oyambira a wopanga laminate kuphatikiza ndi data yowongolera ndondomeko yowerengera m'nyumba, kuyimba zinthu zomwe zizikhala zogwirizana pakapita nthawi mkati mwa malo omwe amapanga.

Machining

Ikafika nthawi yoti mupange PCB yanu, ABIS onetsetsani kuti mwasankha ili ndi zida zoyenera komanso luso lopangira

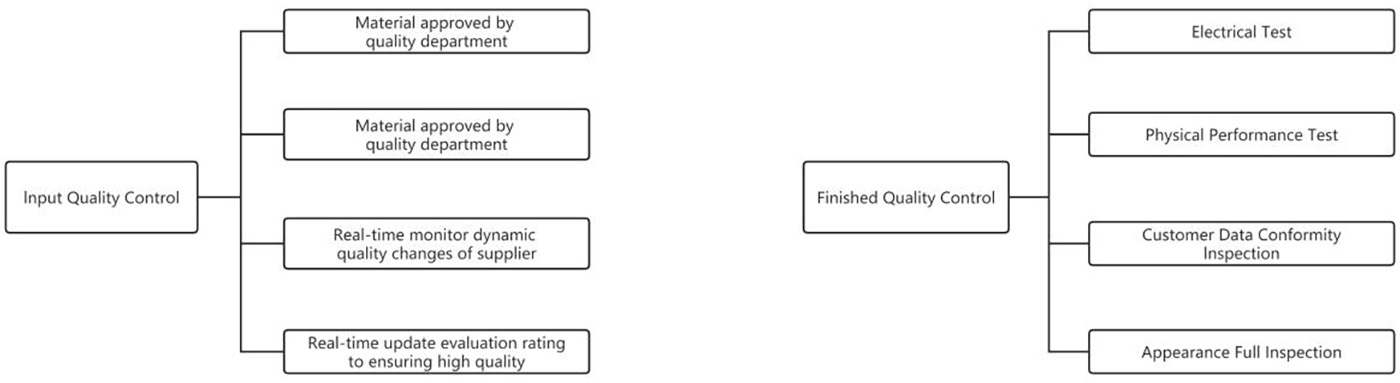

ABIS Quality Mission

Kudutsa kwa zinthu zomwe zikubwera pamwamba pa 99.9%, chiwerengero cha kukana kwa anthu ambiri pansi pa 0.01%.

Malo ovomerezeka a ABIS amawongolera njira zonse zofunika kuti athetse mavuto onse omwe angakhalepo asanapangidwe.

ABIS imagwiritsa ntchito mapulogalamu apamwamba kuti ifufuze mozama za DFM pa data yomwe ikubwera, ndipo imagwiritsa ntchito njira zowongolera zotsogola panthawi yonse yopangira.

ABIS imapanga 100% kuyang'ana pazithunzi ndi AOI komanso kuyesa magetsi, kuyesa mphamvu yamagetsi, kuyesa kuwongolera mphamvu, kugawa magawo ang'onoang'ono, kuyesa kugwedezeka kwamafuta, kuyesa kwa solder, kuyesa kudalirika, kuyezetsa kukana kwa insulating ndi kuyezetsa ukhondo wa ionic.

Satifiketi

FAQ

Ambiri a iwo ochokera ku Shengyi Technology Co., Ltd. (SYTECH), yemwe wakhala wachiwiri padziko lonse lapansi wopanga CCL potengera kuchuluka kwa malonda, kuyambira 2013 mpaka 2017. Tinakhazikitsa ubale wautali wa mgwirizano kuyambira 2006. The FR4 resin material (Model S1000-2, S1141, S1165, S1600) amagwiritsidwa ntchito makamaka popanga matabwa osindikizira amodzi ndi mbali ziwiri komanso matabwa amitundu yambiri.Apa pakubwera tsatanetsatane wa zomwe mukunena.

Kwa FR-4: Sheng Yi, King Board, Nan Ya, Polycard, ITEQ, ISOLA

Za CEM-1 & CEM 3: Sheng Yi, King Board

Kwa pafupipafupi: Sheng Yi

Kwa Machiritso a UV: Tamura, Chang Xing (* Mtundu ulipo: Wobiriwira) Wogulitsa Mbali Imodzi

Pazithunzi zamadzimadzi: Tao Yang, Resist (Filimu Yonyowa)

Chuan Yu (* Mitundu yomwe ilipo: Yoyera, Yomwe Mungaganizire Yogulitsa Yellow, Purple, Red, Blue, Green, Black)

), mawu a ola la 1

b) Maola 2 oyankha madandaulo

c), 7 * 24 ola thandizo luso

d), 7 * 24 kuyitanitsa utumiki

e), 7 * 24 maola kutumiza

f), 7 * 24 kupanga kuthamanga

Ayi, sitingavomereze mafayilo azithunzi, ngati mulibe fayilo ya Gerber, mungatitumizire chitsanzo kuti tikope.

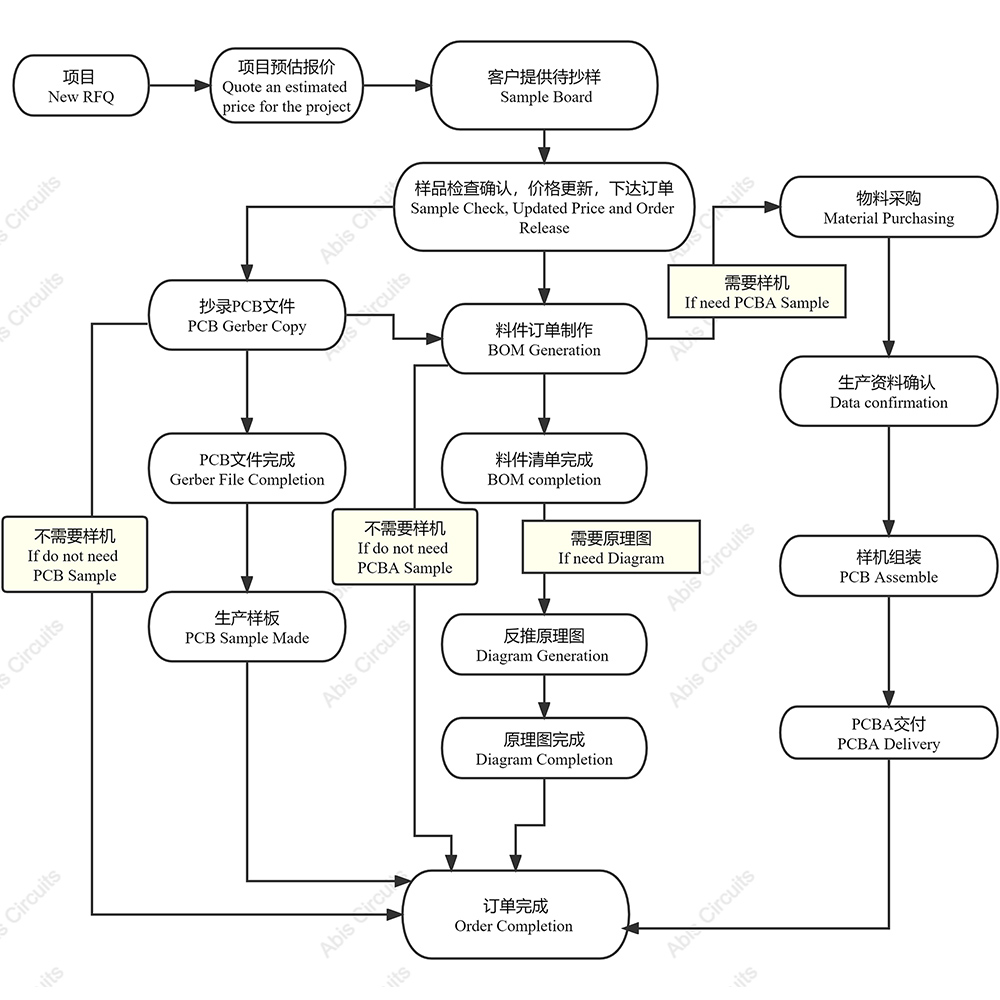

PCB&PCBA Copy process:

Njira Zathu Zotsimikizira Ubwino monga zili pansipa:

a), Kuyang'anira Zowoneka

b), kafukufuku wowuluka, chida chokonzekera

c), Kuwongolera kwa Impedans

d), Kuzindikira luso la Solder

e), Digital metallo graphic microscope

f), AOI (Automated Optical Inspection)

Zafufuzidwa mkati mwa maola 12.Funso la Engineer ndi fayilo yogwira ntchito ikayang'aniridwa, tiyamba kupanga.

Yang'anani pozungulira inu.Zogulitsa zambiri zimachokera ku China.Mwachionekere, zimenezi zili ndi zifukwa zingapo.Sikulinso za mtengo chabe.

Kukonzekera mawu kumachitidwa mwamsanga.

Malamulo opangira amakwaniritsidwa mwachangu.Mutha kukonzekera maoda omwe akonzedweratu miyezi ingapo, titha kuwakonza nthawi yomweyo PO ikatsimikizira.

Njira zoperekera zinthu zidakulitsidwa kwambiri.Ichi ndichifukwa chake titha kugula chigawo chilichonse kuchokera kwa okondedwa apadera mwachangu kwambiri.

Ogwira ntchito osinthika komanso okonda.Zotsatira zake, timavomereza dongosolo lililonse.

24 ntchito zapaintaneti pazosowa zachangu.Maola ogwira ntchito +10 maola patsiku.

Mtengo wotsika.Palibe mtengo wobisika.Sungani pa ogwira ntchito, pamutu ndi momwe zimagwirira ntchito.

ABIS ilibe zofunikira za MOQ za PCB kapena PCBA.

ABlS imayang'ana 100% zowoneka ndi AOl komanso kuyesa magetsi, kuyesa kwamagetsi apamwamba, kuyesa kuwongolera kwamphamvu, magawo ang'onoang'ono, kuyesa kugwedezeka kwamafuta, kuyesa kwa solder, kuyesa kudalirika, kuyezetsa kukana kwa insulating, kuyezetsa ukhondo wa ionic ndi kuyesa kwa PCBA Functional.

ABIS ilibe zofunikira za MOQ za PCB kapena PCBA.

| Mphamvu yopangira zinthu zogulitsa zotentha | |

| Double Side/Multilayer PCB Workshop | Aluminium PCB Workshop |

| luso luso | luso luso |

| Zida: CEM-1, CEM-3, FR-4(High TG), Rogers, TELFON | Zida zopangira: Aluminium base, Copper base |

| Layer: 1 wosanjikiza mpaka 20 zigawo | Layer: 1 wosanjikiza ndi 2 zigawo |

| Min.line m'lifupi/danga: 3mil/3mil(0.075mm/0.075mm) | Min.line m'lifupi/danga: 4mil/4mil(0.1mm/0.1mm) |

| Min.Hole kukula: 0.1mm(bowo lodulira) | Min.Bowo kukula: 12mil (0.3mm) |

| Max.Kukula kwa board: 1200mm * 600mm | Max.Board kukula: 1200mm* 560mm(47in* 22in) |

| Kumapeto kwa bolodi: 0.2mm-6.0mm | Anamaliza bolodi makulidwe: 0.3 ~ 5mm |

| Makulidwe a zojambula zamkuwa: 18um ~ 280um (0.5oz ~ 8oz) | Makulidwe a zojambula zamkuwa: 35um ~ 210um (1oz ~ 6oz) |

| NPTH Hole Kulekerera: +/- 0.075mm, PTH dzenje Kulekerera: +/-0.05mm | Kulekerera kwa dzenje: +/-0.05mm |

| Kulekerera kwadongosolo: +/-0.13mm | kulolerana kwamayendedwe: +/ 0.15mm;kulolerana nkhonya autilaini: +/ 0.1mm |

| Pamwamba pomaliza: HASL yopanda kutsogolera, golide womiza (ENIG), siliva womiza, OSP, plating yagolide, chala chagolide, Carbon INK. | Pamwamba Pamwamba: Kutsogolera kwaulere HASL, golide womiza (ENIG), siliva womiza, OSP etc |

| Kulekerera kwa Impedans: +/- 10% | Kulekerera kwa makulidwe: +/-0.1mm |

| Kuthekera kopanga: 50,000 sqm/mwezi | MC PCB Kupanga mphamvu: 10,000 sqm/mwezi |